VFFS, HFFS and UK Savoury Snacks packaging

The UK Savoury Snacks market is the second largest in Europe after Russia and is fifth in the world! We all love a snack!

Potato crisps are approximately 34% of this total. 96% of which are made from UK home grown potatoes and we sell approximately 10% of our crisp production to Europe.

Over 70% of crisps are sold in small bags of 28g and under and it is thought over 90% of us indulge.

Corkers Crisps made the largest ever bag of crisps in the world weighing in at 1,141kgs, they even sent a pack into space. That really is Savoury Snacks packaging extreme!

Extruded snacks represent a whopping 46% and nuts another 10%. Extruded snacks are things like tortilla chips and cheesy puffs and are produced by mixing ingredients in a high-pressure cooker and then the mixture is forced through a shaped opening. They are then lightly fried or expanded in hot air before the flavour is added.

So, it’s quite a wide-ranging product portfolio requiring many different kinds of packaging and packaging machinery.

Vertical Form Fill Seal Wrappers and VFFS for Savoury snack packaging

As snacks tend be small free flowing items, they are usually best packed using gravity (imagine trying to push peanuts along a conveyor belt!). A multi-head weigher is fixed to the top of the packing machine and the product fed into hoppers which weigh the product and drop the correct amount down a metal tube inside a tube formed from the VFFS packaging film.

The VFFS film runs off the reel around a forming shoulder and wraps around the tube and is sealed down the back forming a long film tube. The back seal can be either a fin seal where the film seals inside to inside or lap seal where the film seals inside to outside. The product is dropped down the tube and the sealing unit seals and cuts the bottom of one package and the top of another. Also known as the end seals. The finished packs drop onto a conveyor belt to be taken for secondary packing.

Many different types of Savoury snacks packaging film can run on these machines.

Some examples are:

- Polypropylene laminates are probably the most widely used packaging film often having a metallised inner web to help extend shelf life. The outside web can be glossy or matt or can be printed with a patterned matt or tactile lacquer.

- Single web polypropylene can also be used for some Savoury snacks and a label applied but these are being replaced more and more by printed laminates

- Paper laminates or paper treated with a very thin heat sealable layer can also be used where a natural look is desired

- Compostable versions are also available including compostable paper laminated to metallised Natureflex which is based on cellulose made from wood pulp

Flow Pack Wrappers and HFFS for Savoury snack packaging

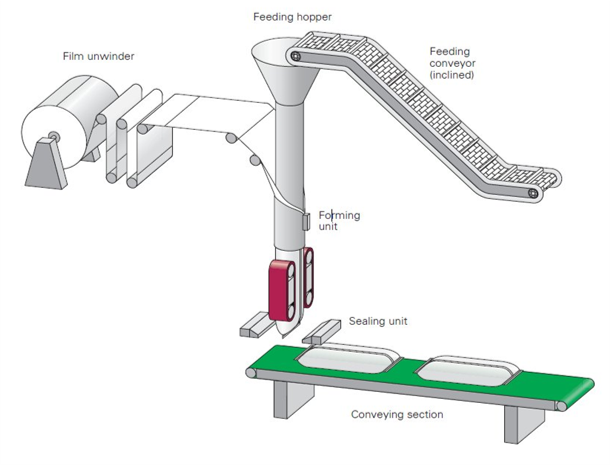

Horizontal Form Fill Seal machine or HFFS for short are used on occasions for Savoury items that are often in a tray! This can be pushed along a conveyor belt using paddles into the packing line. And just to throw another name in they are often called flow wrappers.

How does the packing line and packaging work together?

The bakery product to be packed travels horizontally in a continuous motion through the packing line usually pushed by paddles. HFFS Packaging film is fed from a reel into the machine and the former guides the material to create a continuous tubular shape around the product. After the product has traveled through the former, the two edges of the packaging material are joined together under the centre of the product. The joined edges of the material are then sealed together in a longitudinal fin. Also known as the back seal.

After the longitudinal seal is formed, the product is transported through rotary sealing/cutting jaws. As the cutting head rotates it simultaneously seals and cuts the front of one package and the back end of another. Also known as the end seals. The discharge conveyor carries the finished package away from the sealing and cutting area for any secondary packing.

Many different types of Savoury snacks packaging film can run on these machines.

Some examples are:

- Polypropylene is often used to collate packs of already packed product

- Two webs of polypropylene can be laminated to give a stiffer pack and if the pack is being printed the inks are sandwiched between the 2 webs to give a gloss or matt finish and protect the inks

- Laminated packaging films are also used with a PE sealing layer for products needing longer shelf life and maybe gas flushing for example very dry products like crispbreads for a more robust pack

- Polyester can be used when the product will be cooked or kept warm in the packaging as it is the only dual ovenable material. It can also be printed with special inks and can be perforated to allow steam to escape

Stand up pouches for Savoury snacks packaging

The machinery available for this area is ever growing and can be entry level hand weighed and filled up to where the packing line starts with a roll of film and forms the pouch as well as packs it.

Some examples of products packed in pouches.

The Savoury snack market is wide ranging requiring many different packaging solutions.

Our engineers are happy to help... especially if they get free samples to take away!